Fashion stands as one of the world’s most fast-moving industries, where trends shift weekly and consumer expectations climb constantly. Yet AI orchestration remains largely absent from fashion operations, despite mounting pressure from different systems, and integration challenges.

Supply chain disruptions now routinely delay production and inflate costs. Labor issues persist across manufacturing regions, with workers facing below-living wages and unsafe conditions. These challenges multiply when siloed systems prevent teams from coordinating effectively.

Predicting consumer demand becomes nearly impossible when trends can vanish overnight. This creates a cycle of over-stock inventory costs and waste that manual processes can no longer manage effectively. Fashion companies need more sophisticated approaches to maintain operational efficiency while addressing sustainability demands. The operational barriers facing today’s brands require solutions that go beyond the traditional methods that once worked in slower-moving markets.

How fashion operations work today

Fashion production operates on pathways established decades ago. These approaches create inefficiencies that modern brands find difficult to address without updated systems.

What does the traditional fashion production model look like?

Design to production: a linear process

Fashion companies operate primarily on a “take-make-waste” linear model. The process starts with design concepts and sketches, moves to materials sourcing where fabrics and trimmings are selected. Product development follows, where designs become technical drawings and patterns, then sampling tests prototypes for fit and construction. After approval, detailed tech packs containing manufacturing specifications are prepared before mass production, quality control, and distribution.

Each stage waits for the previous one to finish, creating bottlenecks throughout the pipeline. This straight-line approach prevents teams from working simultaneously on related tasks.

Manual coordination between teams

Communication and collaboration between departments continues as one of fashion’s major operational challenges. Designers, developers, and vendors often work from different file versions, creating constant misalignments. Critical decisions, vendor feedback, and approvals get lost in email threads, turning minor delays into weeks of missed opportunities.

Excel patches and fragmented vendor conversations multiply complexity while slowing decision-making. Teams lack shared visibility, making version control nearly impossible. This manual coordination costs companies growth as projects stall waiting for alignment between departments.

Dependence on outdated planning tools

Supply chain leaders report significant problems with their planning capabilities. About 61% say their tools cannot support real-time decision-making. Fashion merchandisers work with Excel spreadsheets, PowerPoint presentations, and product lifecycle management (PLM) systems designed for aerospace or automotive industries. These rigid systems weren’t built for seasonal cycles or rapid consumer-driven changes.

Many suppliers still request orders by fax machine, showing how entrenched old technologies remain. Traditional planning software can react to problems but lacks prevention capabilities, leaving planners responding to outdated information when new disruptions are already happening. This technology gap creates conditions for excess inventory and operational inefficiency.

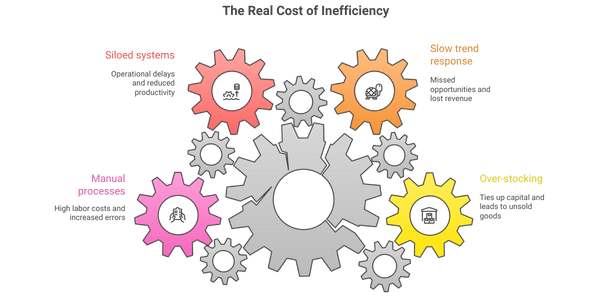

The real cost of inefficiency

Fashion’s glamorous exterior conceals a harsh financial reality. The industry wastes billions annually through operational inefficiencies that better coordination could address.

Over-stock inventory costs and unsold goods

Excess inventory creates staggering financial losses. Fashion companies recorded excess stock worth billions in sales during 2023. This figure represents approximately 30% of all production—meaning nearly one-third of manufactured clothing never reaches consumers.

Luxury brands face particularly acute challenges. Warehousing costs increased 10% in 2023 compared to the previous year, adding pressure to already tight margins.

Lost revenue from slow response to trends

Production cycles cannot match the speed at which trends emerge and disappear. Brands find themselves overstocked with outdated designs or understocked on viral products. Out-of-stock sizes rank as customers’ top complaint. Inaccurate stock purchasing across sizes results in profit losses.

Operational delays due to siloed systems

Disconnected systems cost retailers and brands billions in lost opportunities annually. Fashion companies operate with fragmented systems across creation, manufacturing, and marketing. Teams struggle to align on priorities or respond quickly to market changes. Brands operate without strategic insight into inventory levels, order statuses, and demand trends.

High labor costs from manual processes

Manual labor drives 35% to 40% of total manufacturing costs in cut and sew processes. Manual data entry and reconciliation divert valuable resources from strategic tasks.

What is AI orchestration and how it works

An AI orchestration platform serves as the intelligent control layer that unifies applications, data, systems, and AI agents into a single, coordinated operating environment. It enables organizations to design, deploy, and manage AI-powered workflows that align directly with business goals—ensuring automation is not only fast and scalable, but also contextual and outcome-driven.

How it connects data across the supply chain

Data pipelines form the backbone of AI integration—automated processes that organize, store, and move information between systems. These pipelines enable different systems, apps, data sources, and tools to communicate without human intervention. Fashion companies can establish real-time communication between machine learning models through APIs and connection mechanisms, linking them with various supply chain tools.

Role in automating decision-making

AI orchestration enables intelligent decision-making throughout fashion operations. Orchestration platforms analyze trend data, understand performance drivers, uncover inefficiencies, and interpret demand signals. Historical trends combine with real-time data and scenario modeling to simulate how external factors like tariffs or currency shifts affect sourcing costs, lead times, and inventory positions.

Examples of AI-driven alerts and actions

Sentiment analysis can inform virtual assistants to change their tone or escalate issues to human agents. These systems analyze content, determine sentiment, prioritize based on customer history, and either resolve issues automatically or route them to appropriate teams with context-aware suggestions. This coordination enables fashion companies to run cost-benefit analyses and stress-test lead times before making critical sourcing decisions.

Why now is the time to adopt AI orchestration

Several forces are converging to make AI orchestration essential for fashion companies. The window for gradual adoption is closing as market pressures intensify across multiple fronts.

Rising consumer expectations for speed and sustainability

Consumer preferences have shifted dramatically. Customers now consider sustainable materials an important purchasing factor, with sustainability-focused shoppers willing to pay 15% more for eco-friendly options. One-quarter of consumers actively seek environmentally friendly products. Companies face mounting regulatory pressure.

Increased complexity in global supply chains

Fashion supply chains face unprecedented challenges. Thirty-nine percent of executives anticipate industry conditions worsening. Within this $1.79 trillion global industry, extreme weather events threaten nearly one million jobs across four major production countries by 2030, potentially impacting approximately $65 billion worth of apparel exports.

About 50 million people worldwide live in modern slavery conditions, further complicating ethical sourcing decisions. These factors create a perfect storm requiring sophisticated coordination tools.

Availability of scalable AI tools

AI tools have become increasingly accessible even for smaller brands through modular pricing and seamless e-commerce integrations.

Proven ROI from early adopters

Organizations implementing AI solutions see an average 41% return on investment.

Many fashion brands achieve ROI within just one to three seasons, often beginning with lightweight pilots that prove value in weeks. The evidence base for AI orchestration continues growing as more companies report measurable improvements.

The Future of Fashion Operations is Orchestrated

Fashion operations face mounting pressures that traditional approaches cannot address. Linear processes, disconnected teams, and outdated planning systems create costs that erode profit margins while hampering response to market demands.

AI orchestration provides a unified approach to these challenges. Instead of applying isolated solutions to individual problems, this technology connects disparate systems into a coordinated framework. Fashion companies gain capabilities to analyze market data, understand performance patterns, and adjust operations quickly while reducing waste throughout their supply chain.

This is where Aekyam AI Orchestration delivers a decisive shift. By unifying data, systems, and processes into an intelligent, coordinated framework, Aekyam moves beyond siloed fixes to enable end-to-end operational alignment. It continuously analyzes demand signals, inventory positions, and fulfillment performance, transforming fragmented insights into actionable intelligence.

With Aekyam, fashion brands gain the agility to anticipate change, optimize inventory flows, reduce waste, and respond to market dynamics in real time. AI-driven orchestration doesn’t just improve efficiency—it enables smarter, faster, and more resilient fashion operations built for sustainable growth.

Read Similar Blogs